Intro To Supply Chain Process Automation

This article provides an intro to supply chain process automation, answering the questions:

- Which supply chain processes can be automated?

- Why automate supply chain processes? What is the value?

- What software/tools are used for supply chain process automation?

Last, we wrap up with how you can get started. Let's dive in!

Which supply chain processes can be automated?

In recent years, new technology has made process automation more accessible and effective than ever before.

Perhaps the easiest way to understand the possibilities, is simply to see automation in action, so here is a brief demo with a simple use case: responding to a request for the status of order (or a shipment etc.).

An intro to supply chain process automation demo video

In the demo, the order status is automatically retrieved from a Google spreadsheet and then USPS.com, but the important point it illustrates is that with today’s technology we can automatically understand the intent of emails, assess the identity of the sender, and retrieve relevant order info from any electronic system, even if that means opening a browser and clicking through several pages. While not shown in this demo, we can also automate contacting others for the status by email, text, or even a phone call if necessary.

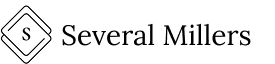

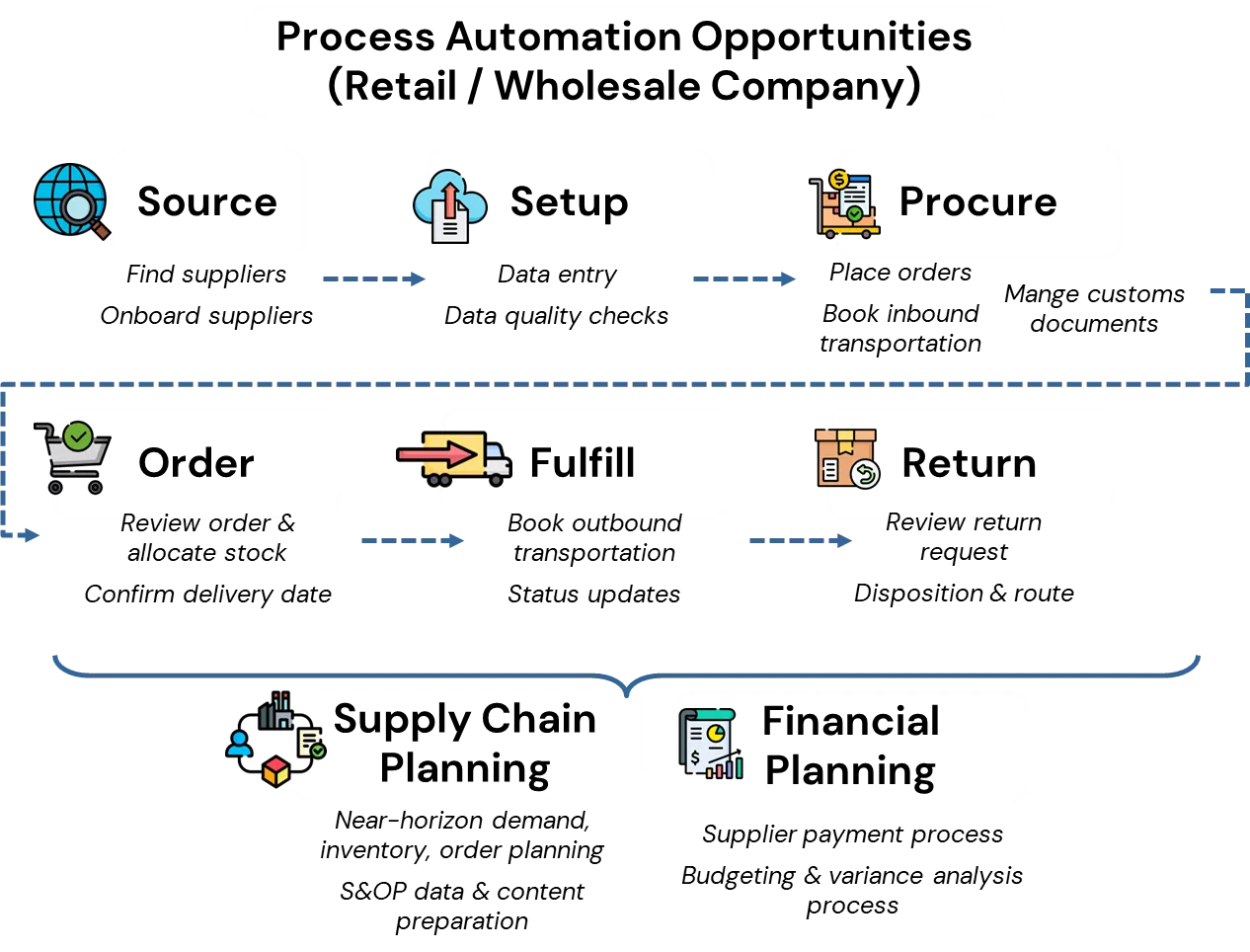

So, which supply processes can be automated? The technology is really at point where the question becomes which process should be automated first? I would emphasize data management, information flows, and near-term supply chain planning work. However, to make things more concrete, here are a few examples loosely based on the APICs SCOR Standard¹:

It’s worth noting that each of these areas can contain a whole world of automation possibilities. For example, there are many new software options aimed specifically at logistics service providers. If you are interested in this space, I recommend checking out the Vooma YouTube channel, which does a good job of illustrating automation for specific brokerage processes.

Finally, one note on physical supply chain processes: everyone has seen the Amazon robots, but that is a larger, more complex project. However, there is a sweet spot with cameras and computer vision, where physical processes like counting inventory, monitoring production, etc. can be automated with a relatively lower barrier to entry.

Why automate supply chain processes? What is the value?

n a world in which the barriers to automation are coming down considerably, the critical questions become: why automate? what should be automated? what should our priorities be?

These are questions at the intersection of technology and business, and this is where our team applies proven consulting frameworks, with an emphasis on Lean Manufacturing and Six Sigma.

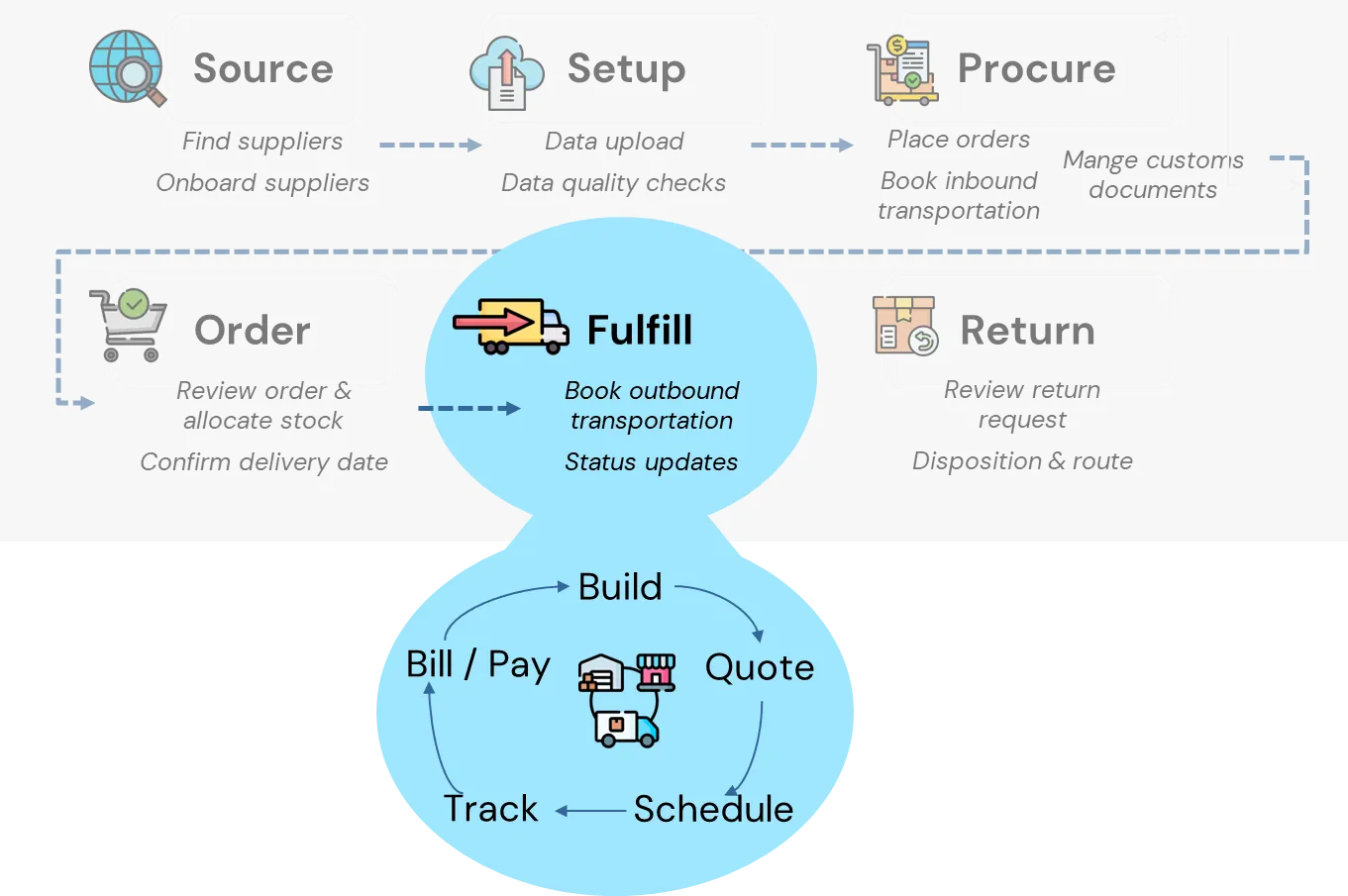

Six Sigma is a methodology for process improvement, and its principles are highly relevant to process automation. Six Sigma approaches the above questions in its Define phase, with tools that include the Project Selection Matrix or Project Viability Model.²

Here is an example:

Definitions:

Value to customer - to what extent can automation enhance the customer experience, driving revenue?

Time savings from automation - how much time savings can be achieved through automation?

Defect rate reduction - higher numbers represent a greater estimated reduction to the defect rate.

Low cost / complexity (to automate) - higher numbers represent lower cost / complexity.

Low barriers to change - higher numbers represent fewer organizational barriers to change.

This sort of framework can be used to prioritize potential automation projects, after which we estimate the long-term ROI. I emphasize long-term, because it should consider the impact to company culture, job satisfaction etc., and other strategic considerations. Ultimately, that long-term ROI is the value of automation, the why behind automation.

What software/tools are used for supply chain process automation?

Finally, there is the question of how. Our approach is software / tool agnostic, meaning that we seek to define the business problem first, and then identify the right software / tools. This can mean selecting an existing business software solution or creating something more custom.

All software / tools exist somewhere along the spectrum shown below:

On the left-hand side, we go in the direction of programming languages, but in our diagram we cut it off at existing open-source, free packages to emphasize that we will likely use these. On the right-hand side, we see fully developed business software solutions, and here we emphasize some of the new players focused on supply chain automation. However, longer established players could go here as well.

The further left we go, the more custom we make things, and our costs become more investment dollars to develop the solution and less monthly usage fees. The further right we go, the more we are selecting from pre-built solutions, which can deliver faster time to value when they are a good match for your needs.

One interesting result of recent technological advances, is that the barriers to develop software are coming down, meaning that the investment costs of building custom solutions are coming down. Either way, we believe that software / tools selection should be based on the problem at hand.

How to get started

Our team follows a 5-step process:

- Discovery - hold initial calls with key stakeholders to gather data and information that will be used in the project selection & ROI analysis phase.

- Project Selection & ROI Analysis - use frameworks like those outlined in the why section above to determine the top 2-5 workflows to automate, then estimate the ROI.

- Proof of Concept - build a lightweight, custom solution to fully or partially automate one of the target workflows. The insight this will provide into costs, challenges, and key requirements to automate these workflows can help tremendously during step 4.

- Software / Tool Selection - establish criteria to support the business case and test different software and tools. Iterate, and select the go forward tech stack.³

- mplementation & Beyond - implement the solution, measure the outcome, and establish controls to monitor the system long term.

You can email jesse@severalmillers.com or book a meeting here to get started.

References:

¹ “SCOR Digital Standard Quick Reference Guide.” Association for Supply Chain Management,https://www.ascm.org/globalassets/documents--files/corporate-transformation/scor-ds-digital-guide_final.pdf

² “Six Sigma A Complete Step-by-Step Guide.” The Council for Six Sigma Certification, Chapter 9: Selecting the Right Project. https://www.sixsigmacouncil.org/wp-content/uploads/2018/08/Six-Sigma-A-Complete-Step-by-Step-Guide.pdf

³ https://www.supplychainshaman.com/how-do-we-stop-buying-planning-software-the-wrong-way/

³ https://www.supplychainshaman.com/thoughts-selecting-supply-chain-software/